Electronics Industry Upgrade:

HMI Facilitates Management Automation

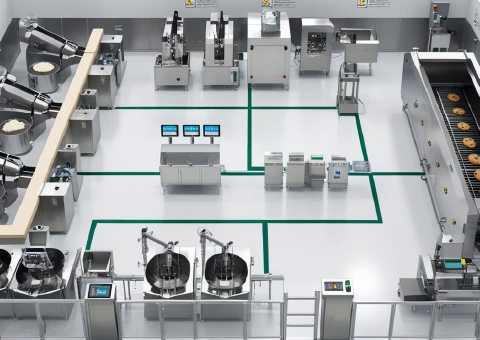

Multi-Device Integration Control

Connection of various devices, including SMT, packaging, and testing equipment, enables centralized management.

Quick Process Parameter Changes

Support for product line changes and recipe storage enhances production flexibility and efficiency.

MES/ERP System Connectivity

Features for production data upload and traceability enhance information integration and management.

Solutions

HMI is widely used in SMT, packaging, testing, and automated warehousing. Weintek's solutions provide graphical interfaces for monitoring, parameter tuning, and alarms, enhancing efficiency, reducing errors, and streamlining processes, while supporting businesses in smart manufacturing and ESG sustainability.

Optoelectronics and Semiconductor

Wafer inspection is vital in the semiconductor and optoelectronic industries. Through wafer analysis, operators monitor manufacturing conditions and enhance quality. Weintek's Gateway series supports SECS/GEM protocols for seamless integration with semiconductor equipment.

Electronic Packaging Process

In electronic packaging, high-precision and high-speed repetitive tasks like pin alignment and encapsulation rely on robotic arms to ensure product consistency and capacity. The HMI connects to these arms via PLCs using EtherCAT and MODBUS for real-time data exchange and command execution, enhancing efficiency and reducing human error.

SMT Production Line

The HMI manages equipment operation, parameter settings, and process monitoring on SMT production lines, enabling quick line changes and real-time anomaly alarms. Operators can access station status and production data through the HMI, which connects to MES systems to enhance efficiency and ensure quality traceability.